Technical parameter

Model number | GLB PLW CD30/GLB PLW CD80/GLB PLW CD100 | Cooling mode | Air Cooling |

Laser power | 30W/80W/100W | Power supply | AC220V±10%,50/60Hz |

Laser wavelength | 915nm±5nm | Maximum power consumption | 850W/1000W/1100W |

Working mode | MODULATION, continuity | Working environment | TEMPERATURE: 10 °C ~ 35 °c; humidity ≤85% |

Working stroke | X:200mm Y:100mm Z:80mm U:360°(Can be customized according to customer requirements) | Optional function | |

Positioning accuracy | X / Y / Z axis: ≤0.05 mm; U Axis: ≤0.1 | ||

Moving speed | X Y Z axis: 100 MM S; U Axis: 100 rpm | ||

Welding line width | 0.6-1.5mm | ||

Software function | Hlweld four-axis laser welding software, intelligent welding process, continuous track teaching function |

Type Characteristics

1, Welding quality is good: Welding seam size precision, firm, airtight and no leakage.

2, Clean Welding: in the welding process resin degradation less, the basic no debris.

3, No welding stress: compared with the traditional welding method, the vibration stress and thermal stress of the products are greatly reduced, and it is not easy to crack at the later stage.

4, Versatile: Able to weld together a variety of different plastics.

5, Shape adaptability: good at welding products with complex shape; able to welding other methods not easy to reach the region, easy to control, with good adaptability.

Product advantage

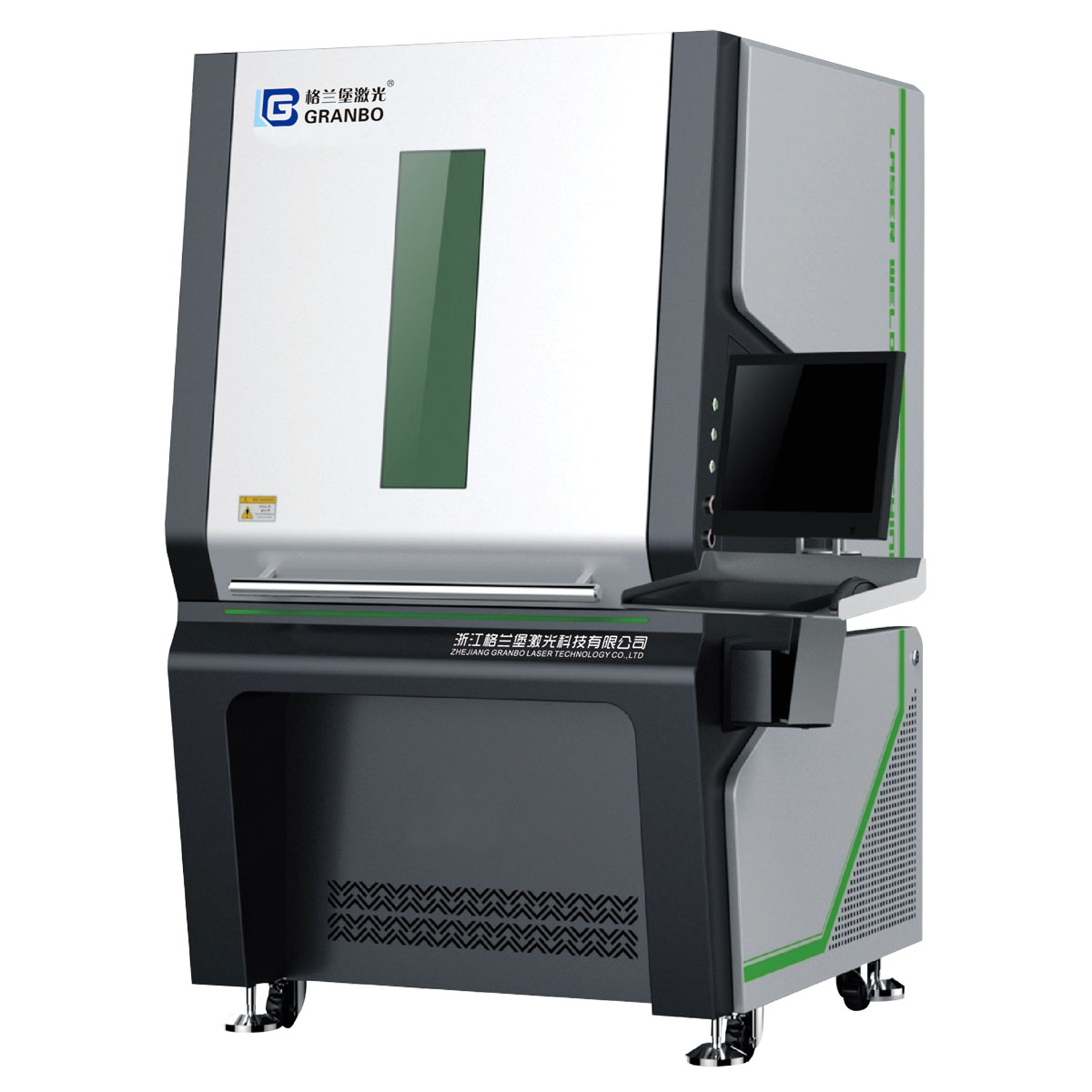

The machine adopts 20-100 Watts medium power semi-conductor laser, suitable for Thermoplastic welding, adopts high reliability industrial control PC, equipped with self-developed special four-axis welding software, can realize flexible intelligent laser processing; It adopts the design of all-enclosed Laser Radiation Protection and integration of machine, electricity, water and gas in line with international standards; double Z axis structure, wide range of work piece size; optical fiber top-up design, safe and reliable, easy to maintain; Optional Wireless Handle, realization of continuous trajectory teaching and remote control function.

Application area

Automobile Parts Plastic, medical equipment parts plastic, electronic products plastic, electrical products plastic, lighting products plastic, etc.